1. why are wooden window seals important?

2. how do i determine the right window seal?How is a timber window seal constructed?

3. What types of timber window seals are there?

1. Sash rebate seal

2. Overlap gasket

3. Glazing gaskets

4. Are there different types of wooden window gaskets?

1. Lip gaskets

2. Hollow chamber seals

5. What material are window seals made of?

1. TPE

2. Silicone

6. What should I do if there is no groove in my wooden window?

7. When should I replace wooden window seals?

8. Are there special care instructions for wooden window seals?

1. why are wooden window seals important?

Window seals for wooden windows are special sealing profiles that are fitted along the edges of wooden windows to ensure an airtight and watertight seal.

Wooden window seals match the appearance of wooden windows and have a natural insulating effect. The rubber profiles influence the performance properties of a window, such as driving rain tightness, air permeability, sound and heat insulation and the operation of a window. This cannot be ignored in view of the increasing requirements of new thermal insulation regulations. They also make a significant contribution to energy efficiency, as they minimize heat loss and therefore save on heating costs. Wooden window seals are therefore not only a practical, but also an environmentally conscious element in every building.

Regular inspection and maintenance of your seals in windows and doors are crucial to ensure their effectiveness. Leaking rubber profiles should be replaced immediately; experience has shown that they become less effective after 15 to 20 years. Proper maintenance can significantly extend the life of the seal. It is therefore advisable to check the seals regularly in order to maintain the full functionality of the windows in the long term.

2 How do I determine the right window seal? How is a wooden window seal constructed?

A wooden window seal is constructed as follows:

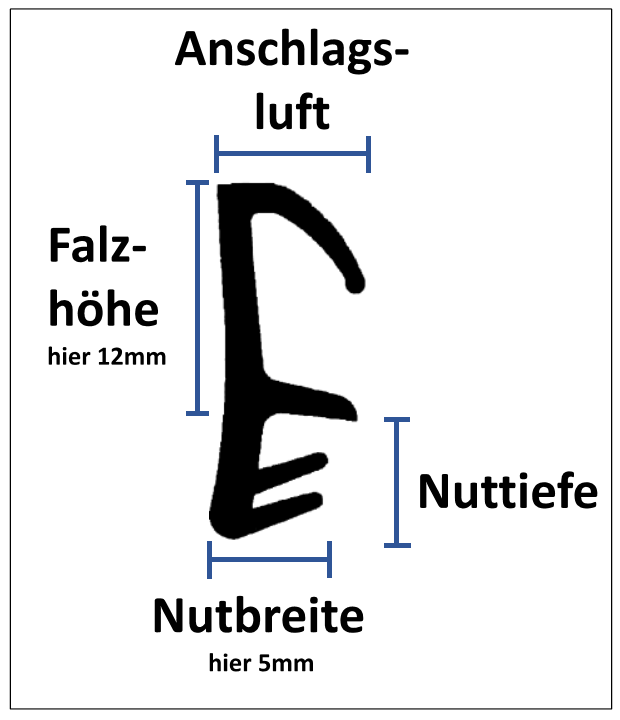

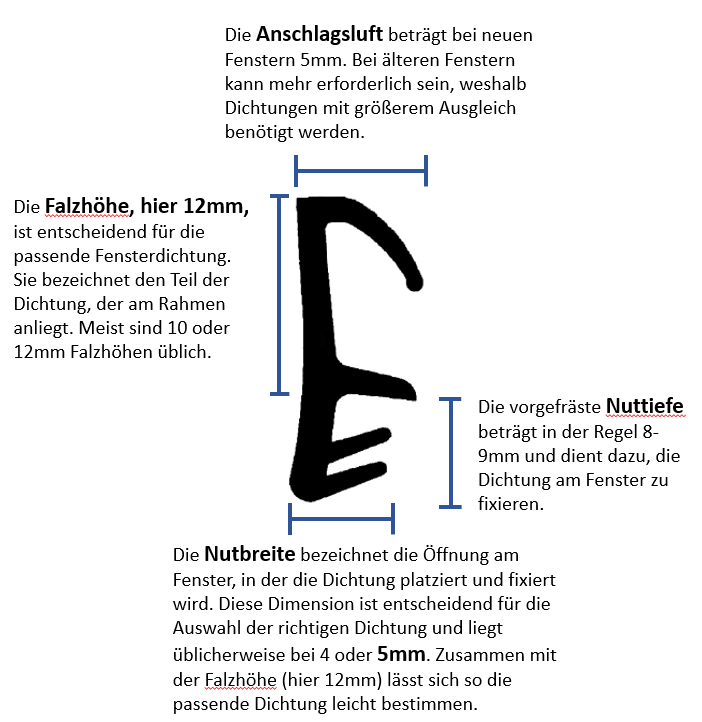

- The stop air indicates the head width or the resilience of your window seal. This is 5mm for new windows. Older windows may require more, which is why seals with greater compensation are needed. The air gap for wooden windows is usually 5mm at the factory, so the new wooden window seal should have a head width or resilience of approx. 7.5 - 8.5 mm.

- The rebate height is the dimension of the gasket support on the frame at 10, 12, 15 or 18 mm. This is very important for the right window seal. Rebate heights of 10 or 12 mm are usually standard.

- The timber window seal is inserted into the (pre-milled) groove depth. It is usually 8 - 9 mm and is used to fix the seal to the window.

- The groove width indicates the opening on the window in which the seal is placed and fixed. This dimension is decisive for the correct choice of gasket and is usually 4 or 5 mm. Together with the rebate height, the appropriate gasket can be easily determined here.

Replacing wooden window seals is not a problem and can be done by any hobby craftsman. In general, a wide range of different seals for windows and doors are available from us. The chance of finding suitable seals, even for older windows, is relatively high.

3. what types of wooden window seals are available?

There are different types of wooden window seals. These seals are used to seal windows and thus minimize energy loss and ensure protection against moisture.

Sash rebate seals

Sash rebate seals are used for wooden windows and doors. The seal is fitted in the rebate of the window sash to ensure an effective seal between the window sash and the frame. The rebate is the part of the window sash that fits into the frame when the window is closed.

Features:

- The sash rebate seal is installed in the window sash.

- Due to its stable design, the sash rebate seal is very efficient in its function.

- The groove width, rebate width and head height of the seal play a decisive role in selecting the right sash rebate seal.

Advantages:

- A reliable seal against unpleasant weather conditions: Draughts, moisture, noise and pollen are kept out.

- Simple installation and maintenance

- cost-effective

rollover seals

Overlap seals are fitted to the outermost level of the window sash, which protrudes beyond the frame. The overlap of the sash is thus pressed tightly against the frame. It is an additional seal that is not absolutely necessary.

Advantages:

- Additional protection against draughts and moisture

- Simple installation

Glazing gaskets are a special sealing element used in windows and doors to seal the connection between the glass and the frame. This achieves effective insulation and improves the energy efficiency of the building.

Features:

- The choice of the appropriate glazing gasket depends on factors such as the thickness of the glass, the frame material and the individual requirements for tightness.

- The pane must be removed to find out which gasket is involved and to determine the cross-section of the gasket.

- Professional installation is particularly important here and should be entrusted to specialists if you have no previous experience.

4. are there different profiles of wooden window seals?

There are two main types of wooden window seals:

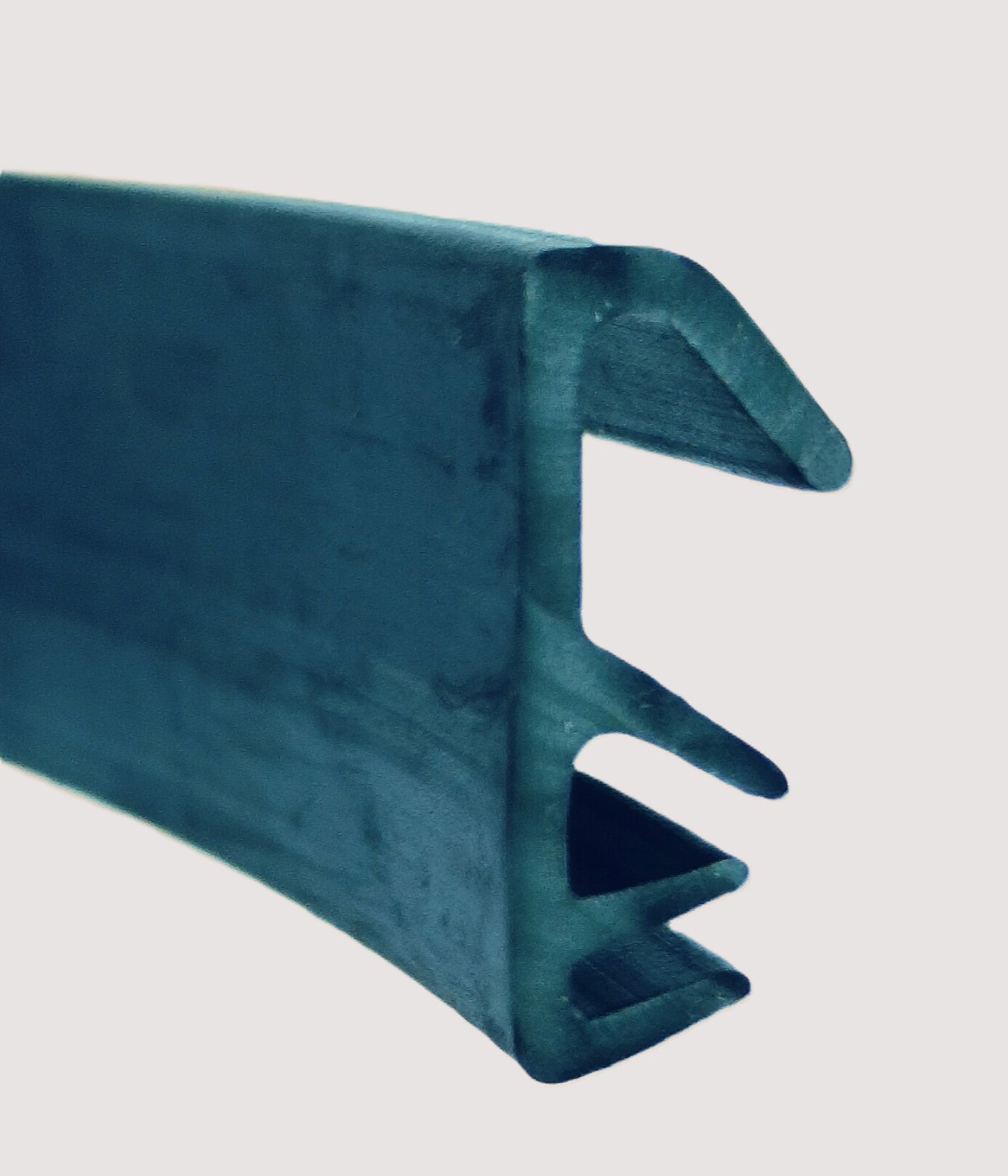

| Lip seals consist of one or more flexible lips that are pressed against the frame when the window or door is closed. The seals provide an effective seal against draughts and moisture. They adapt well to the contours of the window. |  |

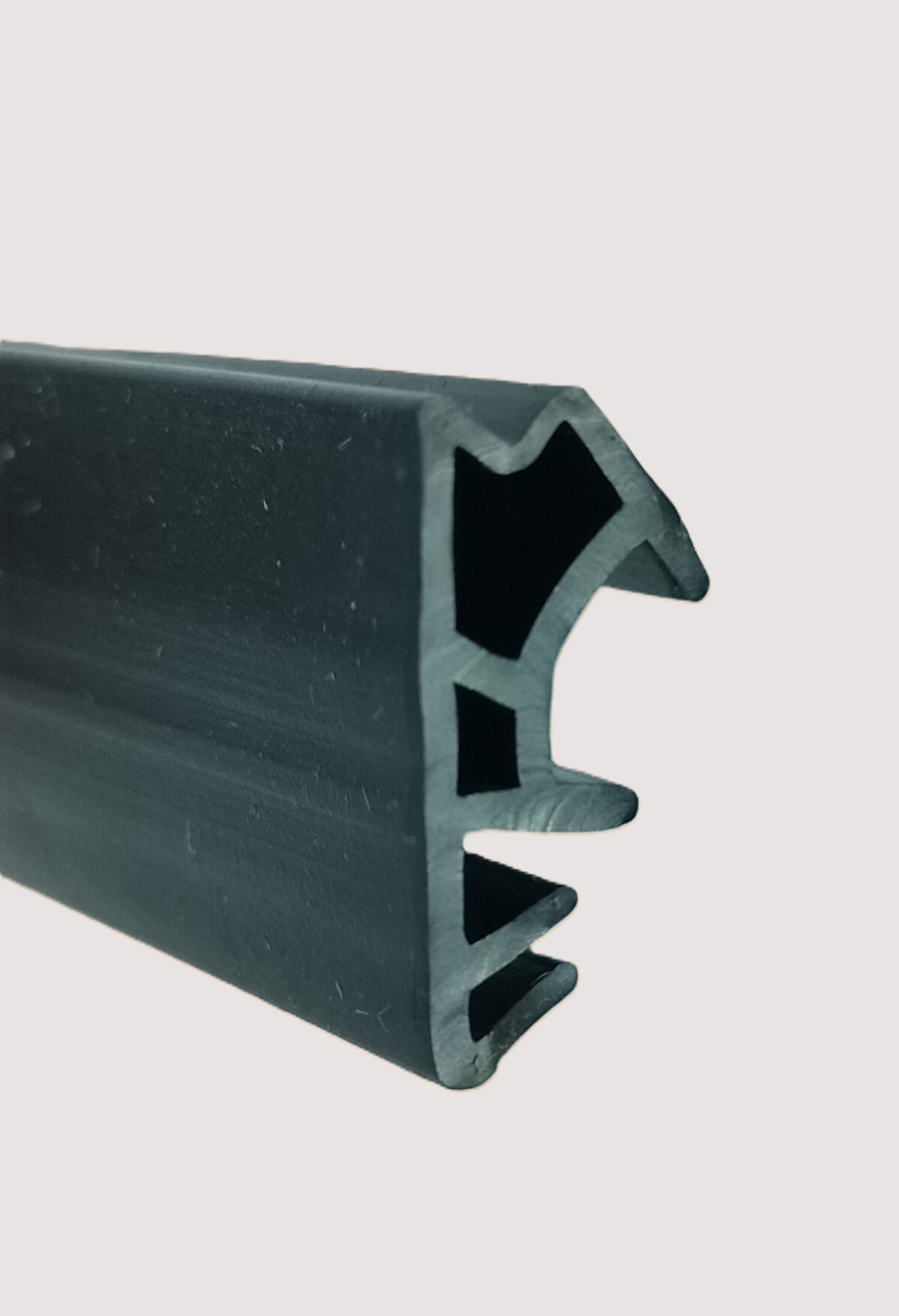

Hollow chamber gaskets When the window is closed, the air is compressed with this type of seal. As a result, the window sash closes more gently. Hollow chamber gaskets have a high restoring force, which means they return to their original shape after opening. |  |

Both types of gasket are easy to fit. It is important to check and maintain the gaskets regularly to ensure efficient window sealing and save energy.

5. what material are the window seals made of?

There are different types of wooden window seals, each made from different materials.

TPEseals combine the practical properties of rubber with the processing advantages of thermoplastics. These rubber seals are particularly flexible and ensure that the window seals tightly to keep out draughts and moisture. They are available in various colors such as black, brown and white. Due to their flexibility and durability, rubber seals contribute significantly to the thermal insulation and energy efficiency of wooden windows.

Silicone seals provide effective insulation against wind and rain, which helps to improve the energy efficiency of the window. We use a special type of silicone sealant that is particularly durable, maintenance-free and UV-resistant. As a result, we guarantee a long-term and reliable seal that meets the requirements for any type of wooden window.

6. what to do if there is no groove in my wooden window?

There is now the option of milling a 3 mm groove in the window sash and fitting a new rubber seal. Special silicone profiles are used to retrofit new window seals for this type of window. This process is very time-consuming and should only be carried out by a specialist company. These are often old buildings with box-type windows.

Fun fact: Until the early 1960s, wooden windows were manufactured without any grooves for window seals. At that time, leaking wooden windows could only be additionally sealed with the adhesive seals known from advertising. From the 1970s until today, wooden windows are generally manufactured with a groove to accommodate a window seal. In this case, sash rebate, forend or stop seals are used to seal new windows.

7 When should wooden window seals be replaced?

Depending on the degree of wear and tear, window seals should be replaced after 15-20 years. Due to years of temperature-related and mechanical influences, their function deteriorates over time. It is therefore advisable to regularly check and, if necessary, replace the seals to ensure optimum sealing and energy efficiency.

8. are there special care instructions for wooden window seals?

Yes, there are special care instructions for seals on wooden windows. To maintain the service life and functionality of seals on wooden windows at

, special care instructions must be followed. This includes the regular cleaning of frames, seals and hinges as well as the

use of gentle cleaning methods such as rinsing water. Especially in winter, it is important to keep the seals dry to prevent moisture and mold growth. Condensation should be wiped off regularly to keep the seals intact. A regular inspection for damage or wear is also advisable. By following these care instructions, problems such as draughts or moisture ingress can be avoided and the energy efficiency of the windows improved.